Sorry, now sold

3″ scale Fowler single cylinder traction engine for completion and commissioning.

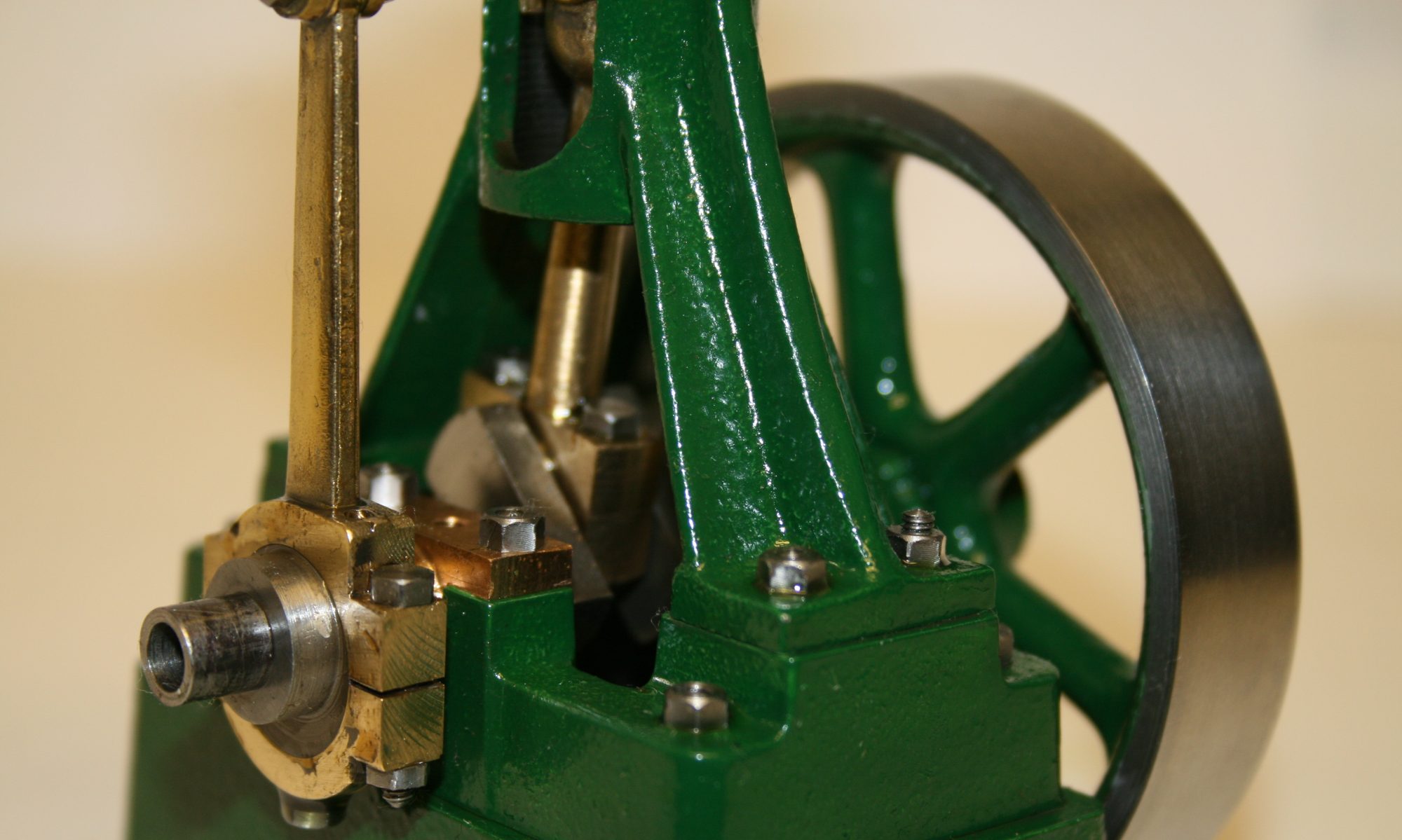

To the MJ Engineering design.

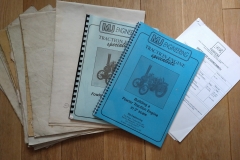

With steel boiler manufactured by Franklin & Bell, works order number: FB349 with hydraulic test certificate to 200PSI issued by Watkins Engineering Limited dated 2 March 2000. Boiler paperwork consists of Franklin & Bell certificate of conformity, hydraulic certificate and 7 pages of materials inspection certificates.

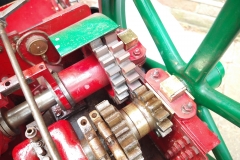

The flywheel turns – although is tight – and the drive gears slide on the splines to engage the drive to the wheels.

The mud hole door has not been sealed, so as a result I’ve not been able to check the engine on air. Given that door has never been sealed, I doubt that the maker ever pressurised the boiler. Having removed the mud hole door, I looked at the internal surfaces of the boiler that are visible – I wouldn’t be surprised if it hasn’t seen any water in it since the day it was tested. I’ve got a couple of photos of the tubes and boiler crown which I can share if you message me.

There are 15 sheets of drawings plus the construction guide from MJ engineering.

In terms of work done, it looks pretty much complete. My observations on what needs to be done are …

- lubricator to be sourced, installed & linkage finished & connected

- cowling around offside rear wheel rubs against wheel

- offside rear hub cap to be fitted – looks like there is a cap that fits

- half round “engineer leeds” badge to be fitted to smoke box – this item is present

- “John Fowler & Co No 11298 Leeds England” badge to be fitted to cladding – this item is present

- forward / reverse lever does not move fully forward to the point of engagement, hole that the push rod passes through needs to be fettled

- something is rubbing during part of the cycle of rotation of the flywheel/piston stroke; could be the water pump eccentric strap against the crankshaft, couldn’t quite pin down where it was coming from

- several bolts/nuts/split pins missing

- curve in the body work to rear of coal tender looks a bit bashed, chance to apply panel beating skills or to rework!

- two part oil splash guard that goes under the motion is there, but not fitted. Looks like it has taken some punishment whilst not being fitted, might be best to remake

- air damper push rod needs to be adjusted to increase movement in the air damper

- seal around the mud-hole

- adjust pipework to water lifter so that it does not fowl the storage lid on right hand of the tender

- rework copper trim to cladding around mud hole

- add rubber tyres to wheel rims

- fix loose water tank breather pipe

- investigate 1/8″ of lateral run out on flywheel

- investigate 1/4″ lateral run out on rear wheels

- bevel gear on governor doesn’t engage as crisply as it should

- most importantly, new batteries for the lamps!

I wouldn’t claim that the above is an exhaustive, but it is what I’ve seen whilst checking this engine over.

Shipping will be via a large pallet to UK mainland (non-highland/island) addresses

For further photos of this item are shown in the gallery below