Sorry, now sold

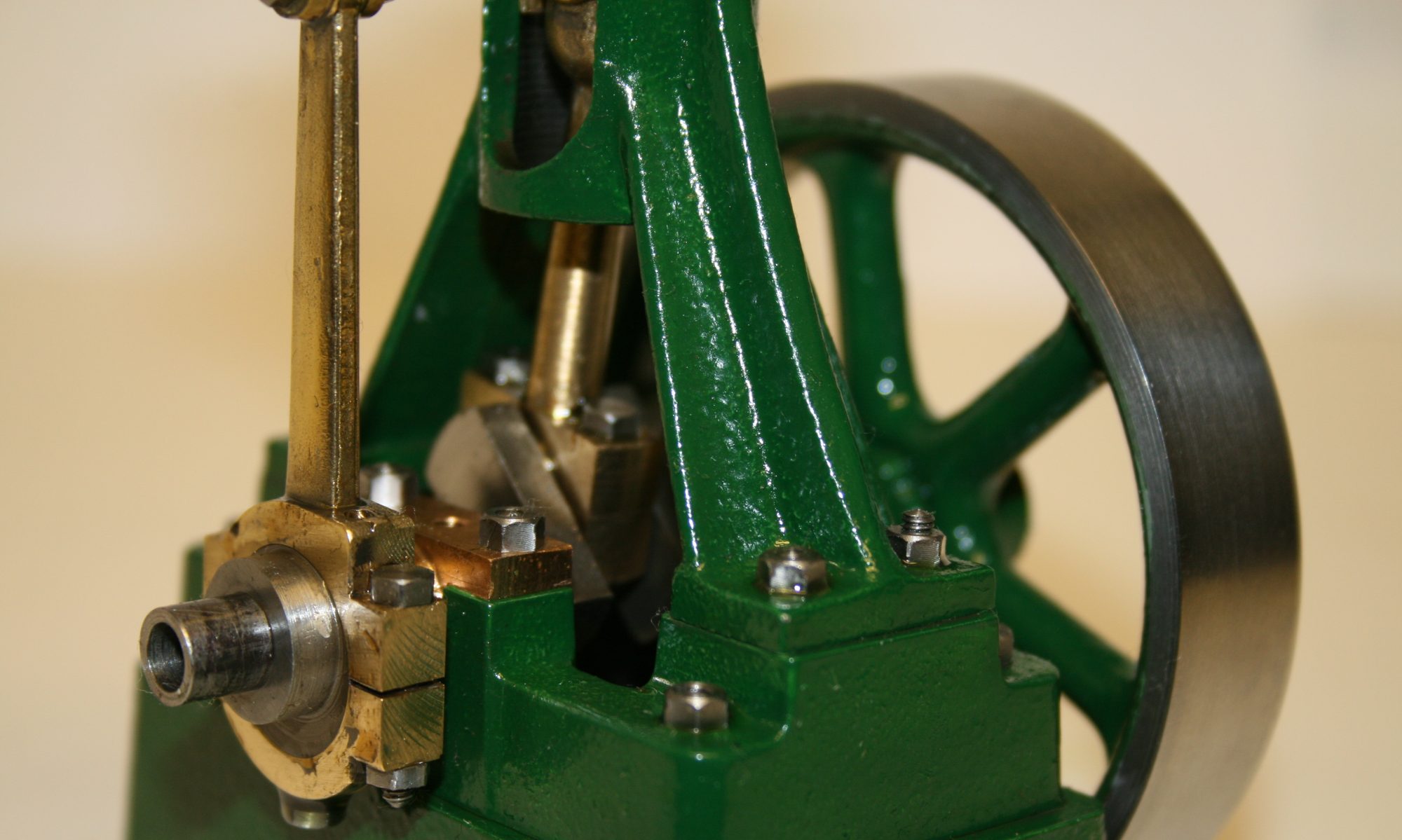

This is a Grimston Milling Machine, one of a small batch of Beaver Model “A” machines that were re-badged as such.

As per the Beaver Model “A”, it has a 3 T-slot table measuring 28″ x 6″, with longitudinal travel of 15″, a cross feed of 7.5″ and a vertical movement of 13.75″. Further information about the Beaver Mill can be found on Tony Griffiths excellent lathes.co.uk website here.

It is fitted with a longitudinal power feed drive to the table and the 32T + 48T drive gears are present, meaning table speeds of 2 or 4 inches per minute can be achieved. Interestingly, the speed guide fitted to the gear cover retains the Beaver branding.

It is powered from a standard 240V power socket, with a 3 phase converter located in the base of the mill providing the feed to the 1HP motor that drives the spindle, and the 0.125HP motor that drives the table. There isn’t currently a separate master switch fitted, so in its “as is” state it runs straight away when plugged into a power socket; if that is a switched socket, that could provide the means to turn it on / off. The table power feed is turned on / off using the Dewhurst switch mounted on the left hand side of the mill. Although direction of table travel can be controlled via this switch, best to always switch to “forward” so that when the power feed is engaged via the mechanical control on the table, the table runs in the correct direction so that the autostop disengages properly when the end stop is reached.

Also included are a number of milling accessories that fit into the spindle

- Jacobs drill chuck

- Clarkson cutter holder plus collets

- Fly cutter

- Boring head

It looks like there is still a coolant pump within the base of the machine, and that this would be operated by the switch to the rear of the left hand side of the base. However, this pump has not been tested, and it might not function. There is also a belt cover, although to fit it the intermediate drive spindle needs to be moved backwards which increases the overhang of the motor at the rear, and longer length drive belts would be needed. Mounting pins would also need to be made to secure the belt cover to its fixing points.

The mill is a heavy item and weighs around 450kg. The base, column and head can be split if the weight of needs to be reduced in order to move it into your workshop.

Collection in person of this item is available. Alternatively, shipping to GB non-remote postcodes with Monday to Friday anytime delivery is available for the price given in the listing . If shipping to Highland/Remote/NI postcodes is required or Saturday or AM / PM delivery, please contact me for the additional cost. The mill will be bolted onto a pallet, with the head rotated round by 90 degrees so as to fit within the allowable pallet dimensions.

Further information can be seen in the video and the photo gallery below…