Sorry, now sold

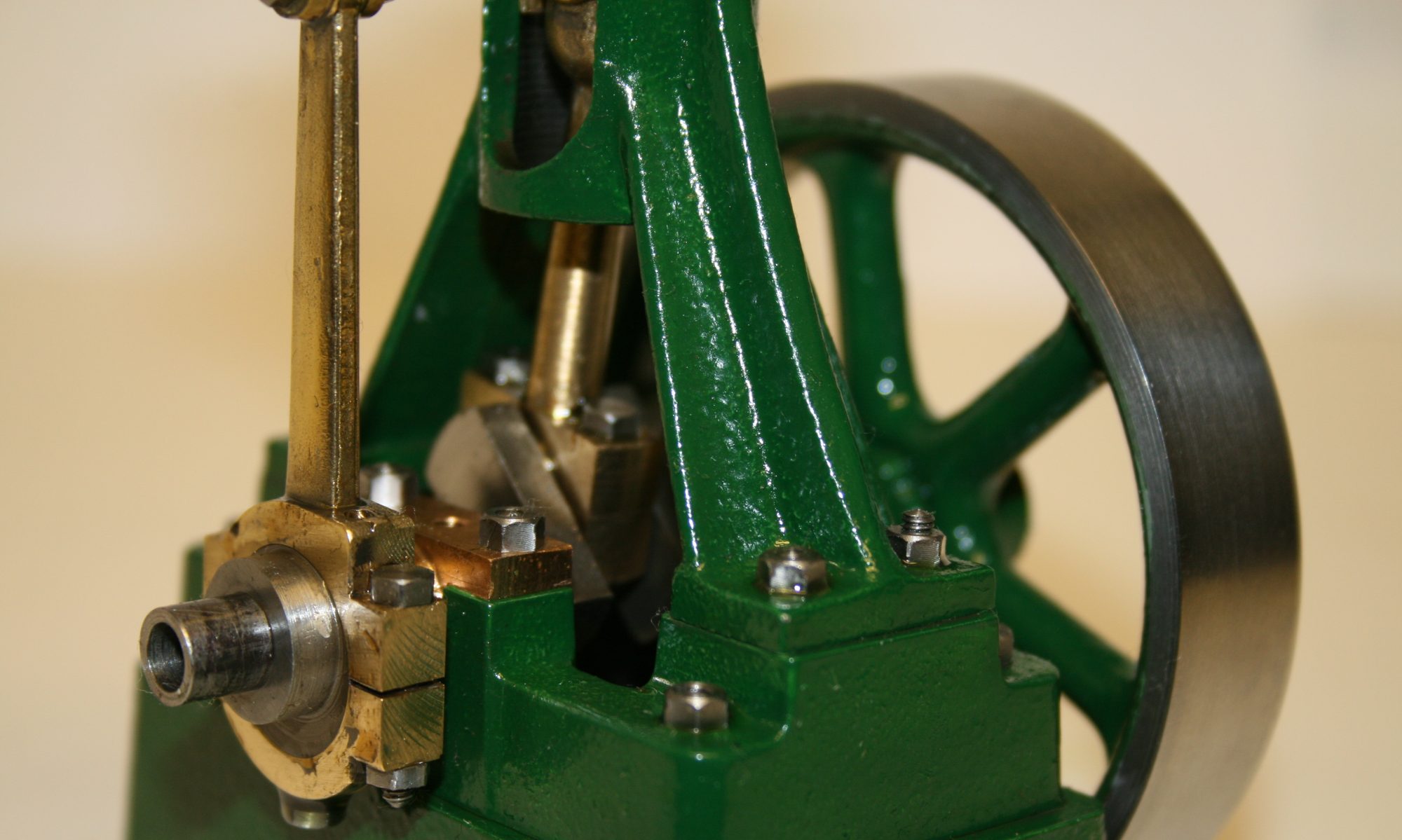

This is a Hobson geared head H7 lathe with serial number 7 / 217 that has been fitted with Myford quick change gearbox serial number QC70172.

According to the excellent lathes.co.uk, the first example of an H7 bore the serial number 7/101 so this is the 117th instance of this model. Elements of the Hobson H7 had a strong resemblance to the Myford ML7 such as the tailstock and topslide. In turn, this made it an attractive upgrade to add a Myford gearbox to the H7. Further information about this item can be founds on the lathes.co.uk website – well worth a read.

The spindle has a 1 5/8″ x 8 t.p.i. threaded nose that accommodates 3MT tooling. The tailstock accepts 2MT tooling.

It is fitted with a single phase 240V HBM motor mounted on the headstock.

Also included with this lathe are the following accessories

- 4″ Burnerd 3 Jaw self centreing lathe chuck with inside & outside jaws plus key

- 5″ 3 Jaw self centreing lathe chuck with inside & outside jaws plus key

- 5″ 4 Jaw independent jaw lathe chuck plus key

- 7 1/2″ face plate

- Quick change tool post

- Five 250-001 quick change tool holders

- 250-002 quick change tool holder

- 250-010 quick change knurling tool

- Parting off tool holder

- Myford style fixed steady adapted to fit the H7 bed

- Rear parting off tool

- 3MT collet holder and draw bar for spindle, and 15 collets sized from 1/16″ to 1/2″

- 2MT drill chuck 1-10mm plus key

- 2MT & 3MT fixed centre

- 2MT live centre

Also included are the original change gears, gear cover etc that would have been used to drive the lead screw before the quick change gearbox was fitted. Note that the Myford gear cover back plate on the left hand end of the lathe has a repair to it – the strengthening plate is visible in one of the photos.

Shipping to UK mainland areas ( excluding Highland postcodes ) on a pallet is available. The oil in the gear head and gear box will be drained for shipping, so you will need to refill them as part of commissioning this lathe in your workshop. I will also remove the motor from its bracket on the headstock so as to reduce the risk of its weight causing any problems during shipping – it is a simple task to refit it back into its cradle.

A short video of this item can be seen here and further photos are in the photo gallery below.