Sorry, now sold

This is a Warco VMC Milling / Drilling Machine Turret Mill with the serial number 77102. On the makers plate there is a dymo label in the date field saying 1986.2 – not sure if this is the actual date as on other Warco machines I have seen that the first two digits of the serial number relates to the year of manufacture. Whether is it a 1977 or 1986 model, it is certainly an earlier version of the model that Warco currently sell – this version doesn’t have the fine feed to the quill that the current model has.

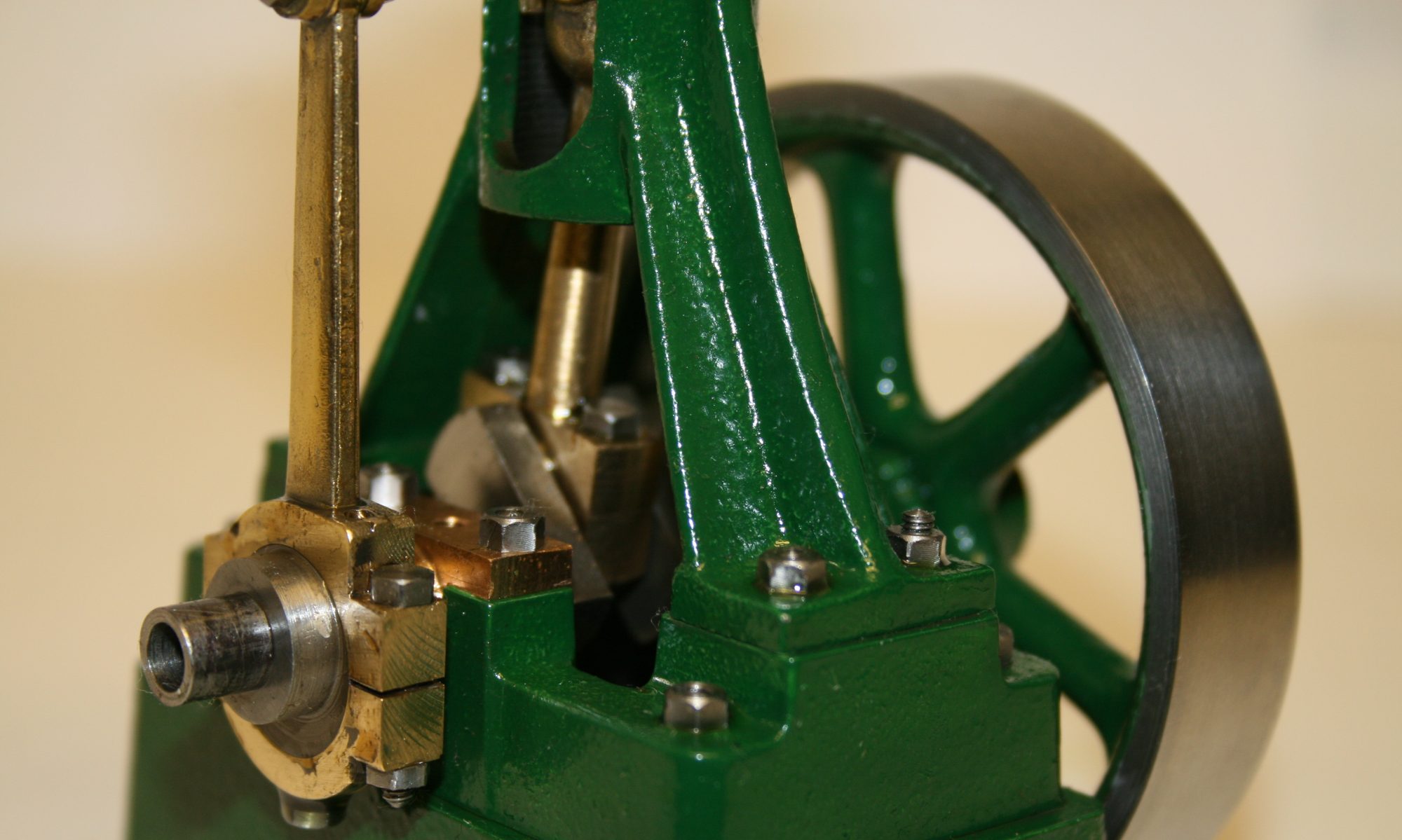

It has a 3MT spindle, and there is a 12mm draw bar plus a Jacobs #36 drill chuck + key. Please check photos to see the condition of the table, there is a circular chink to the middle slot just left of centre.

There is a 0.5HP motor fitted with a recent NVR master switch plus the ability to change the direction of rotation of the spindle.

There are a couple of lifting eyes provided the side of the main column which help when lifting this heavy item. The current Warco model weights in excess of 400kg, so the weight of this item is probably in a similar ballpark!

The mill has recently been primed and repainted with Paragon paints ‘Warco’ enamel paint – for some reason a previous owner painted part of it in dark green, so the fresh coat of paint is more in keeping with the original colour. Again, please check the photos to see the finish of this machine.

Collection in person is available, in which case probably best that the head, body and base are separated for transportation.

Alternatively, shipping via a couple of pallets is available to GB mainland addresses (excluding highland / remote areas), with the base on one pallet and the main body + head of the mill on another pallet. I will remove the motor + mounting plate from the head to avoid undue stress on the motor mounting pin during transit – in turn, this means the electrical switch box will be removed from the side of the mill knee. I will also remove the four handles from their spindles to avoid them being knocked. Straight forward to fit these items when you commission this mill in your workshop. Note that a couple of the welded angled seams to the rear of the upturn on the tray have ‘popped’, so they might need a bead of silicon if they need to be made liquid proof.

Photos of this item are in the gallery below ….