Milnes Type R lathe – Sorry, now sold

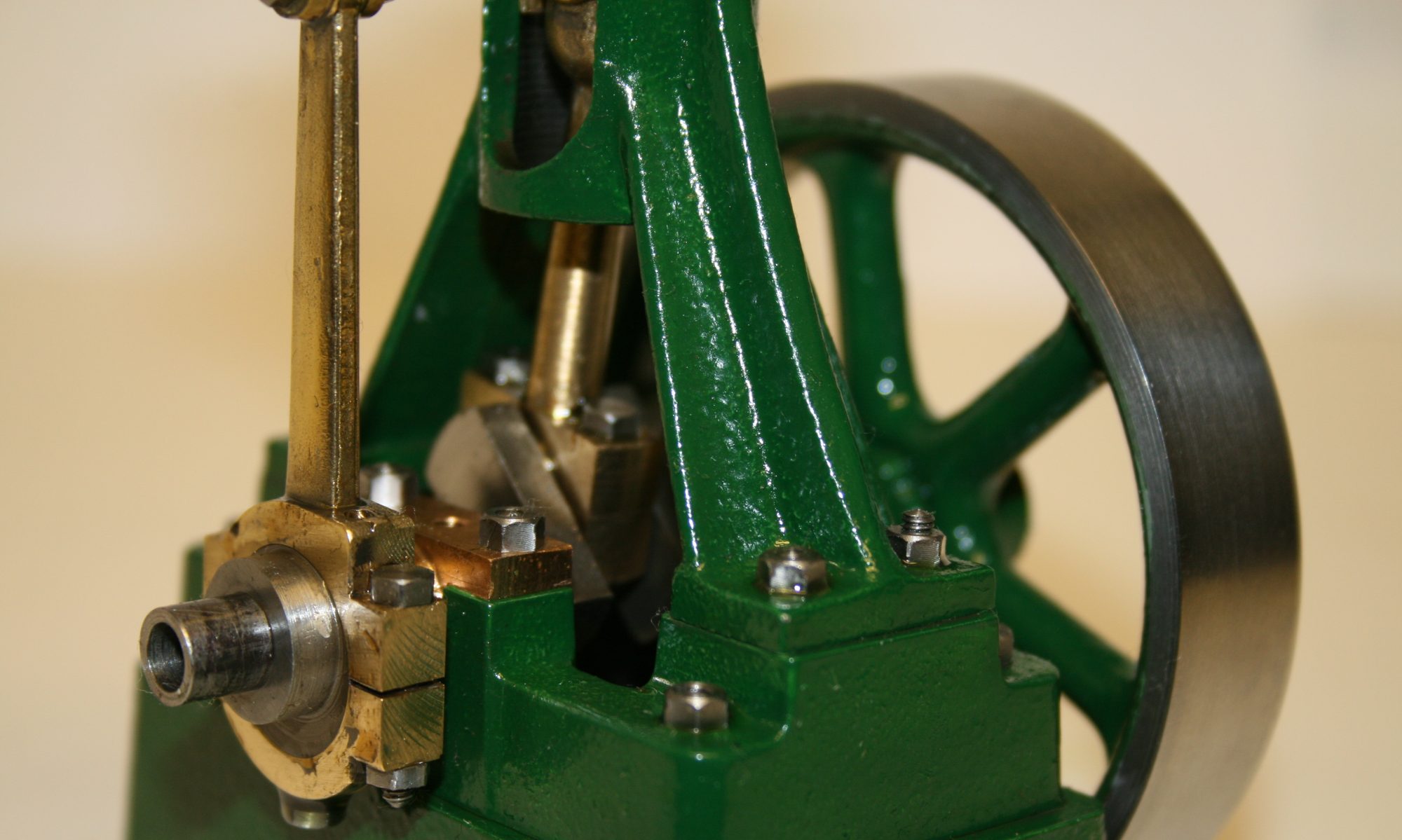

Milnes Type R lathe – circa mid 1930’s. Manufactured by Henry Milnes of Bradford, England. Supplied by Buck & Ryan Euston Rd & Edgware Rd, London NW.

According to lathes.co.uk the Milnes Type R lathe was a heavily-built and well-specified machine, enjoying a reputation as being the “Rolls-Royce” of small lathes.

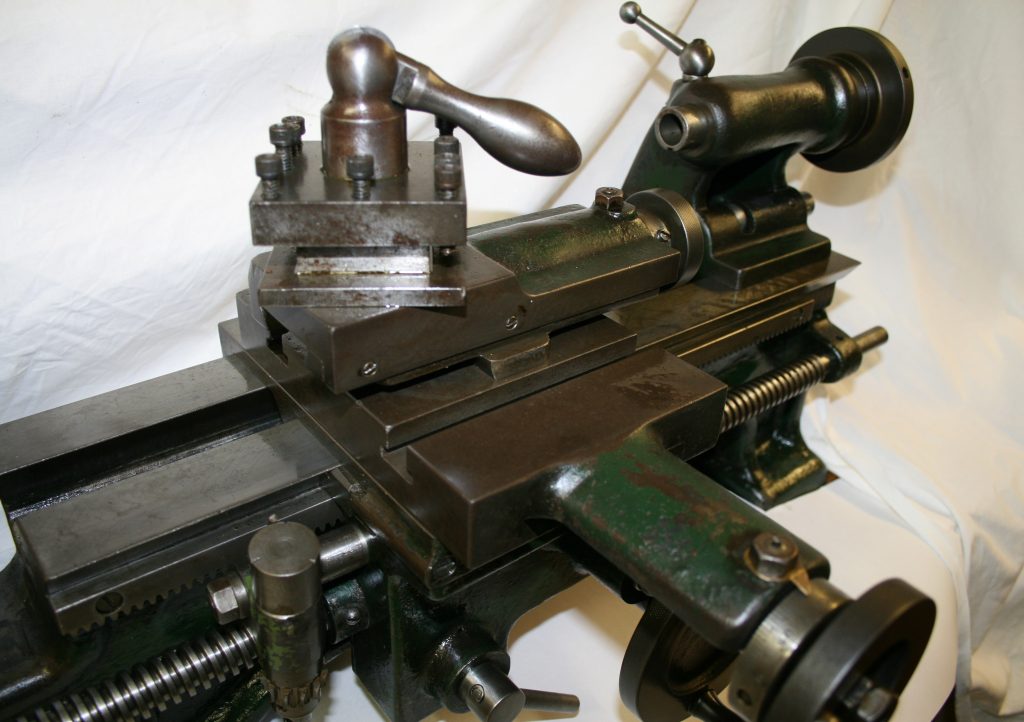

This lathe has benefited from a full strip down and deep clean, with all oil ways being blown through with compressed air. Upon reassembly all screws on the jib strips have been adjusted until stiff and then backed off. The head stock has been re-calibrated to ensure parallel alignment to the travel of the tool post as it moves along the bed. Guidance will be given so that you can make adjustments as part of your regular maintenance routine.

Lifting this lathe is a two (strong) person task. It will fit on the table of Clarke lifting table. Alternatively it can be stripped right down to its component parts, enabling one (strong) person to carry the bed single handed, possibly even up stairs! Guidance on how to reassemble and re-align can be given.

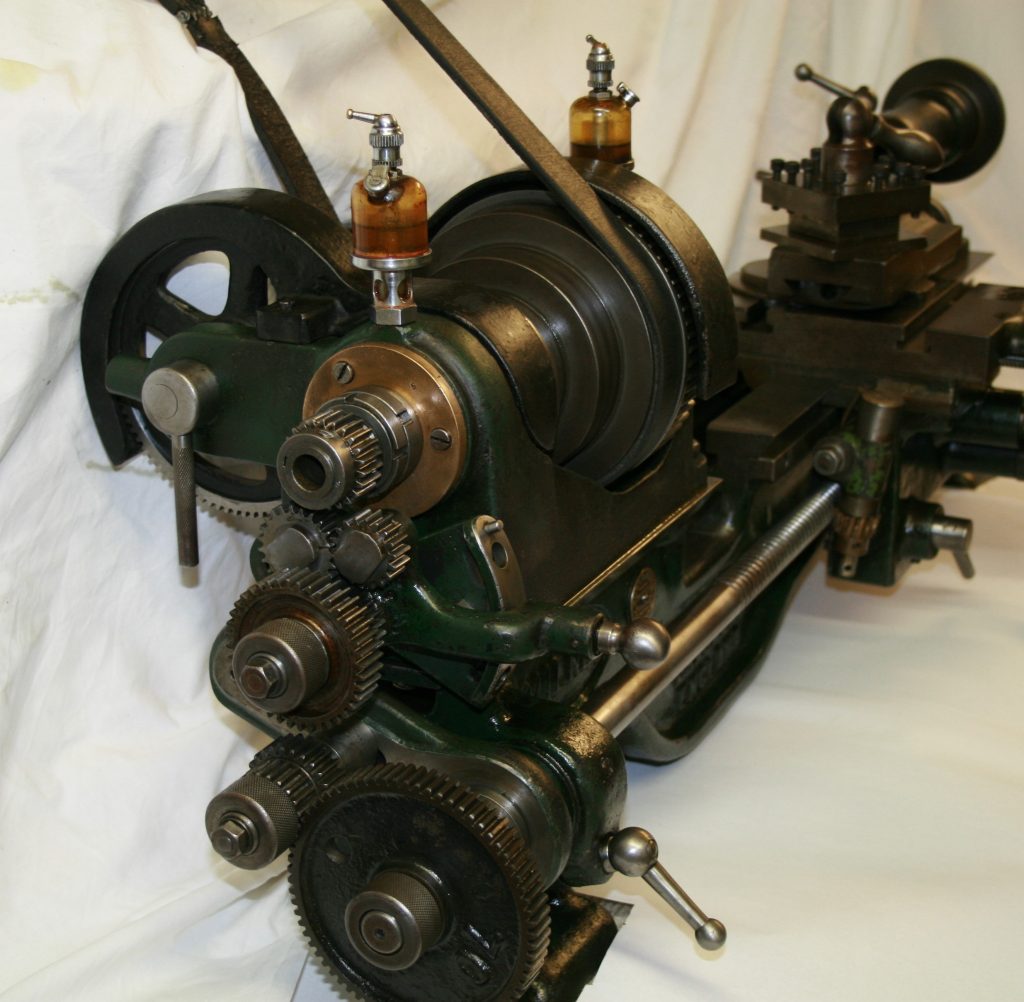

Lathe specification

- 1 1/4″ x 8TPI Spindle. 1/2″ through bore of spindle.

- 4″ x 20″ bed, with 12″ swing in the gap.

- 2MT tail stock

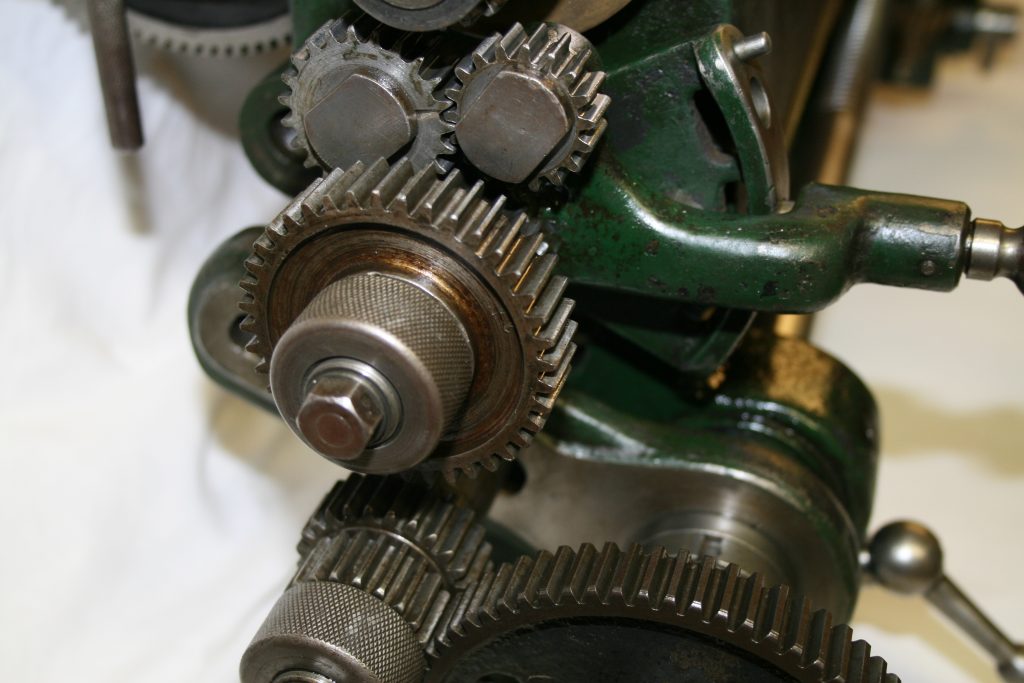

- Back gear

- Thread cutting capability

- Toolpost

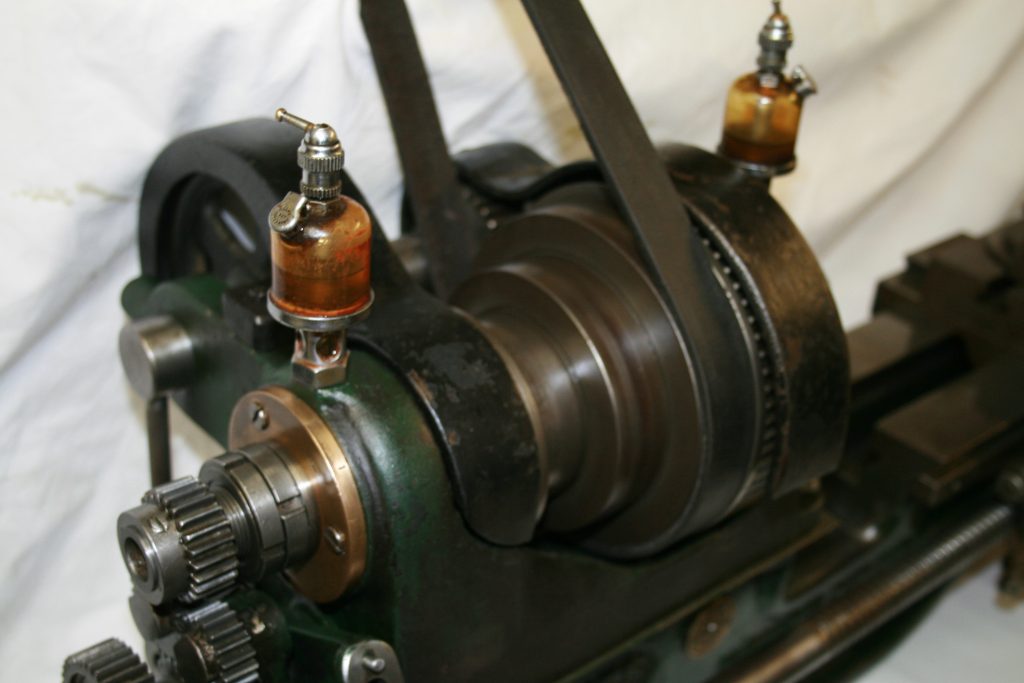

- Headstock oilers

Also included

- 3 jaw self centering chuck – 4 1/4″ diameter. Victoria. Made in England. 2 sets of jaws for internal / external holding of workpiece. Plus chuck key.

- 4 jaw independent chuck – 6″ diameter. The Burnerd. Matching set of jaws and body – number 34865. Made in England. Plus chuck key.

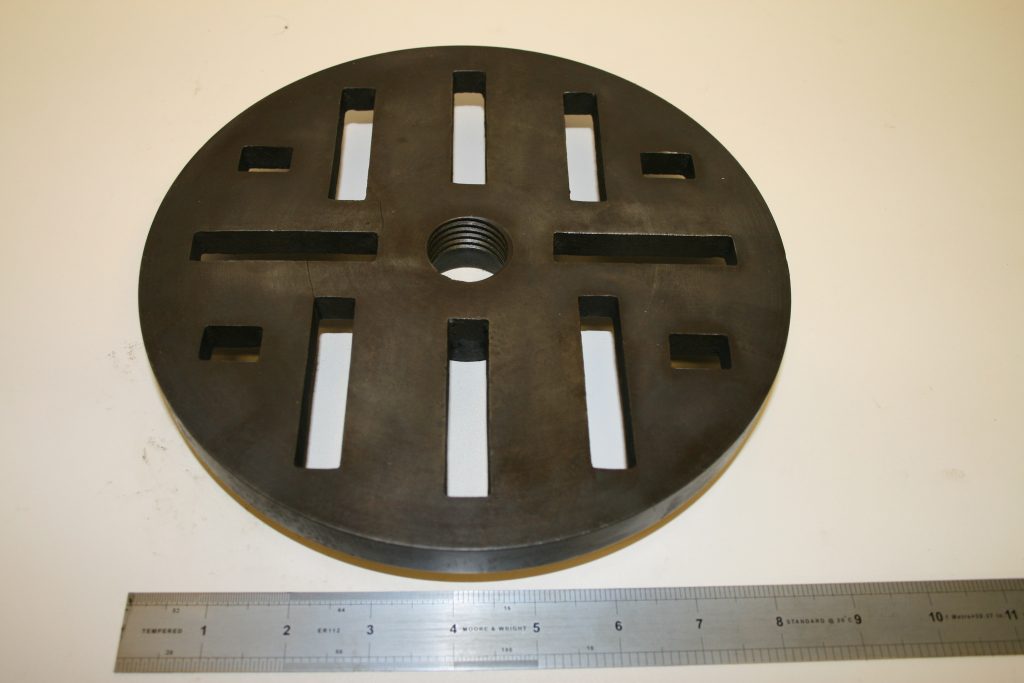

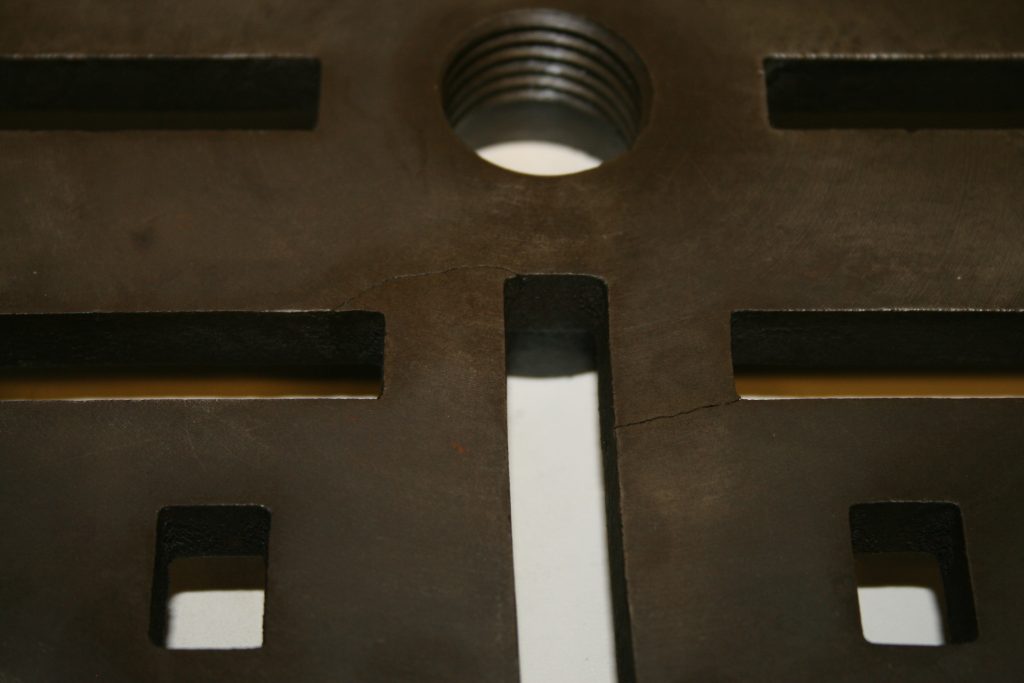

- 9″ sloted faceplate. NB there is a crack in the casting between two slots traversing the slot between them.

- 4″ chuck / dog faceplate.

- 2mt 1/2″ “Modern” chuck. Plus chuck key (unbranded chuck key, not the Jacobs one in the photo).

- Carrier that will accept a work piece around 1″ that mounts onto the saddle cross slide dovetail

- Thread cutting change gear wheels

- 20T, 25T, 30T, 40T, 2x50T, 55T, 60T, 63T, 65T, 70T, 75T, 80T, 90T, 95T, 100T

- Chip tray

- C Spanner to adjust nuts on spindle and lead screw.

- Whitworth spanners for maintenance

The lathe is belt driven, and also included are

- Crompton Parkinson 0.75 BHP 240V AC motor. NB some refurbishment done to re-sheath brittle insulation around internal wiring. Guidance will be given on how to check integrity of insulation as part of your regular maintenance routine.

- 2 x 3 step pulleys to take drive from motor to shaft

- Shaft pulley, with approx 5 1/2″, 4″, 3″ diameter drive wheels. NB there is a crack to the rim of the small end of the pulley

- Shaft + mounting bearings

Price is based on customer collection. Please contact me about delivery options. A custom pallet will be needed to ship, which will be charged at construction cost.

Photo gallery

Individual photos