Sorry, now sold

5″ Britannia project for completion – to the James Perrier design using Norman Spink castings

I’d describe this a being a ‘mid-stage’ project where work to date has progressed in parallel across many areas of construction.

In terms of what is there, I think I can identify the following part built items, assemblies or components …

- main frames with driving wheels fitted plus leading and trailing pony truck

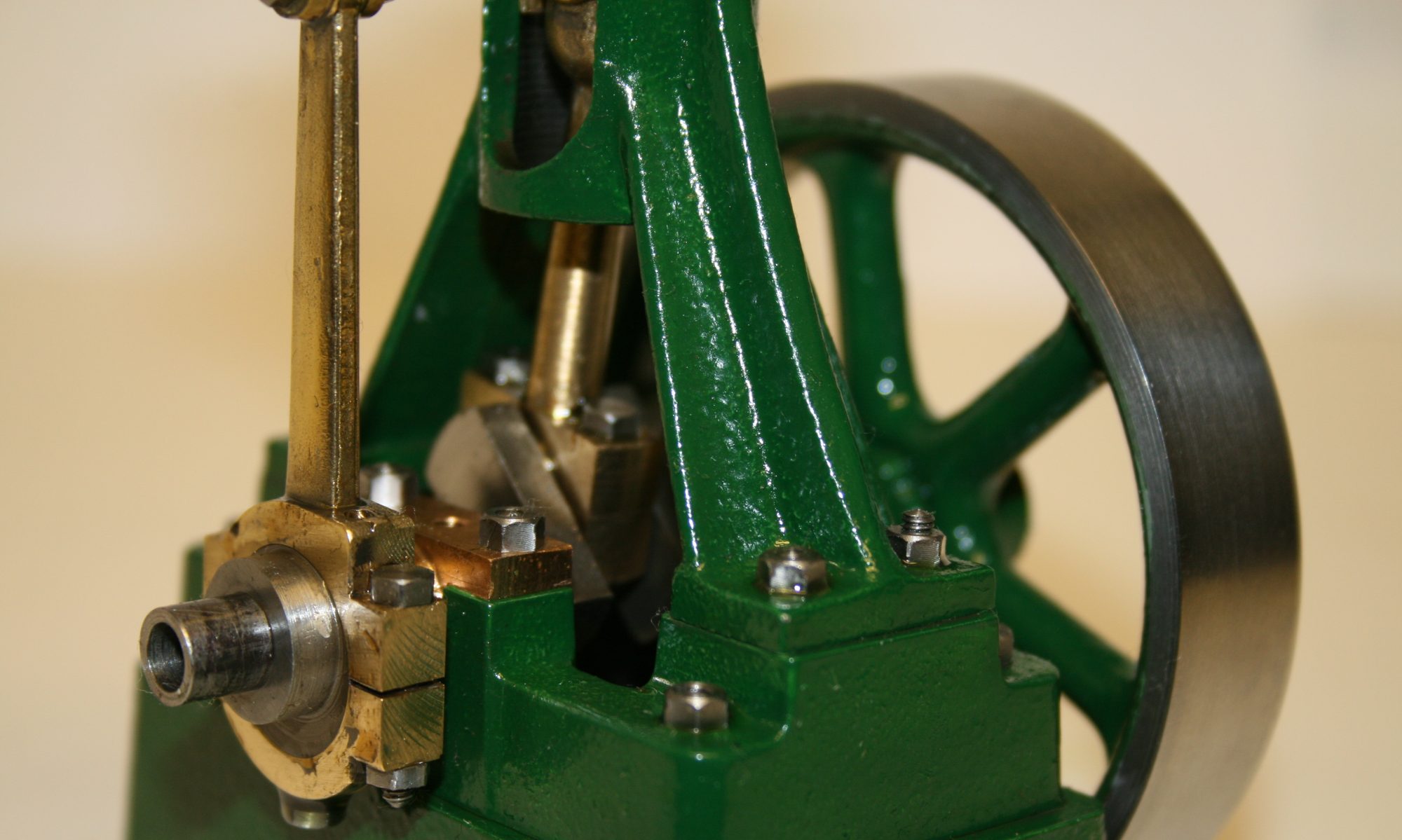

- cylinders machined and fitted, with much of the motion work present. Some of the studs that hold items in place are not present.

- smoke box + door + chimney and front brasswork

- Oliver Cromwell name plates

- brake linkages, hangers, blocks fitted – note one of the linkages has a bend in it, not sure if it is meant to.

- brasswork for cab

- brass plate work for boiler backhead

- chassis for tender plus brake linkage mechanism

- brasswork for tender, note that some inner parts of the tender looks like they has been assembled then disassembled at some point in time

- ash pan and grate

- silver soldered boiler

- no documentation

- back head stamped “Tested 160PSI 0594” – indicating a hydraulic test was conducted on this vessel in May 1994 – before the date when CE marking was required for commercially constructed boilers

- back head also stamped with the identity “COM490” plus an oval shaped stamp containing the letters “B&E” – only google reference I can find indicates this might have been a Bishop Ellis boiler, or a boiler previously provided for a Winson kit. If you know what this mark indicates, please do let me know!

- some further work is needed before another hydraulic test can be done on this vessel. Whilst it is straight forward to temporarily seal the various bushes with suitable blanking plugs, there is a unthreaded bush on both the front fire tube plate and backhead for the blower. Either the blower pipe needs to be fitted, or a way to temporarily seal these holes is needed for a pressure test. There is also the fixing hole between the two pressure valve bushes through which the steam collector will be held in place once fitted. Not sure of the best way to seal this hole temporarily for a pressure test, unless the steam collector is properly fitted.

- super heater tube work

- Additional boxes with various components

- two pressure valves

- two top clacks

- many further items

There is also a set of 21 drawings, plus a Norman Spink price list dated 1978 indicating the likely start date for construction of this model.

The model is currently mounted on a frame that will allow it to be rotated to allow access to the underside.

Plenty of work done already to kick start construction but much still to do with this project, Blackgates have this model in their catalogue and should be able to supply missing castings etc required to complete.

Please check the photos carefully to see what is included, I must stress that it is a part built model and there are likely to be many components missing / yet to be fabricated.