Sorry, now sold

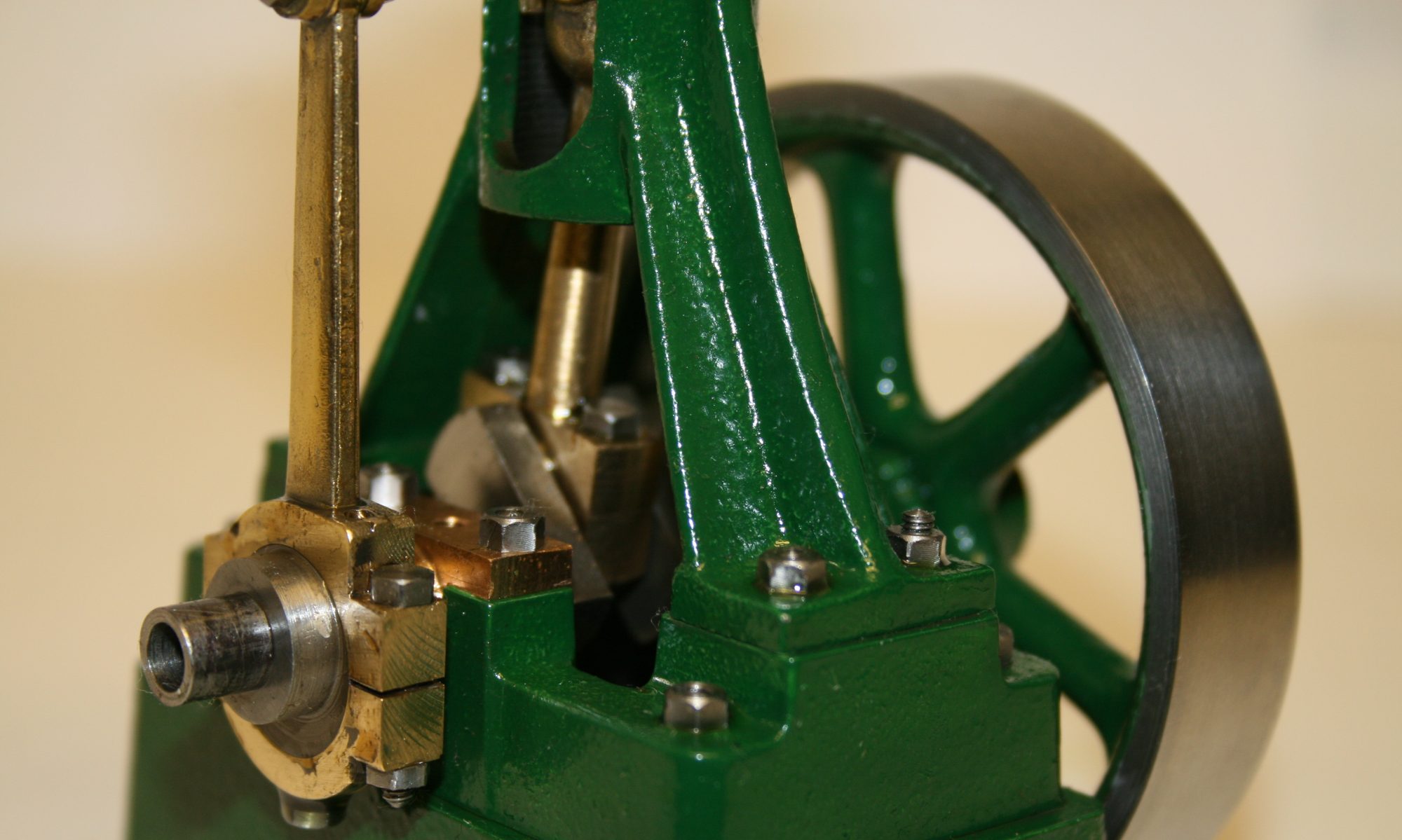

This is an Excel PL1118 lathe Model 5HK, serial number 5256-051 dating from June 1995, with one owner from new.

It is powered by a 0.75KW 3 phase motor, with inverter, enabling it to run from a standard 240V single phase supply. The inverter supply also has the benefit of enabling variable speed control of the spindle – although note that when the operating frequency is reduced towards its lower range, the relay on the power safety circuit drops as there is insufficient power to hold the relay. The inverter unit needs to be mounted securely (on your workshop wall??) as part of commissioning this lathe in your workshop.

Normal operation of the lathe is controlled via the switches on the front panel of the lathe, with forward and reverse operation of the spindle available.

The two spindle gear head levers, together with the two drive pulleys provide 12 fixed spindle speeds – there is a bit of a knack to selecting the spindle speed via the gears which shouldn’t take too long to master.

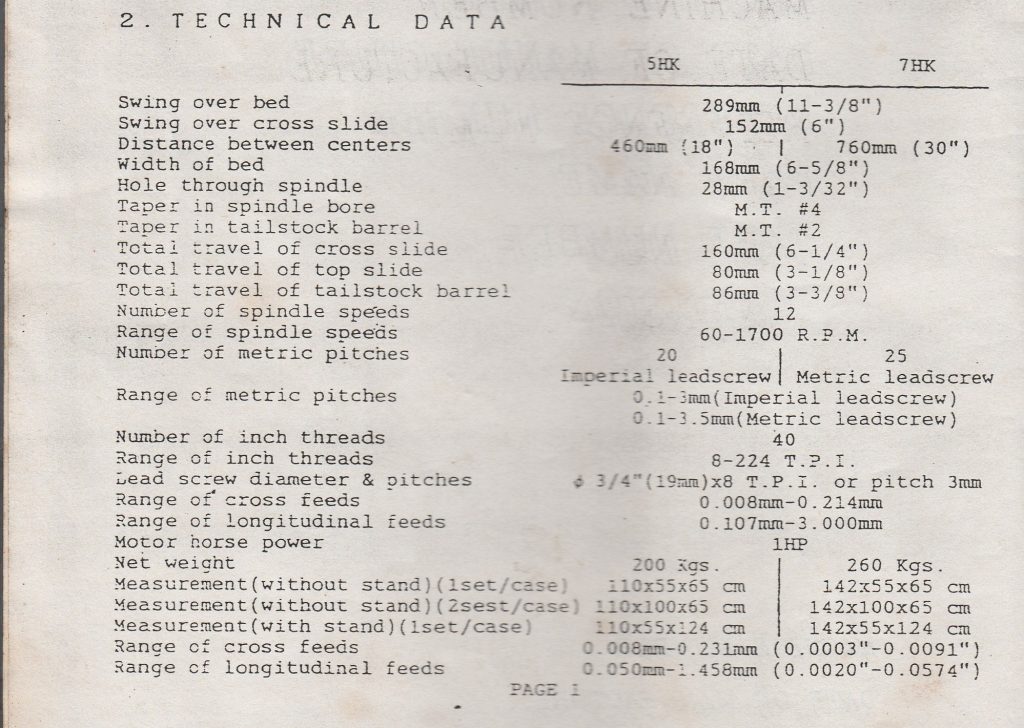

The technical data for this lathe is as per the following extract from the operating manual …

Also included are the following items

- 125mm Pratt Burnerd 3 jaw self centering chuck model 9580-01305 with internal and external jaws + key, with D3 camlock mounting

- 160mm Bison 4 jaw independent chuck + key, with D3 camlock mounting

- 8″ face plate with D3 camlock mounting

- Fixed steady

- Thread dial indicator

- Selection of change gears

- MT4 to MT2 adaptor for use in spindle

- MT2 Fixed centre

- MT2 dril chuck for use in tailstock

Also included is the tray and heavy duty stand seen in the photos, plus the original operating manual and parts list.

Shipping to GB non-remote postcodes with Monday to Friday anytime delivery is available for the price given in the listing. If shipping to Highland/Remote/NI postcodes is required or Saturday or AM / PM delivery, please contact me for the additional cost. The lathe and the stand will be bolted onto separate pallets for delivery. The apron and headstock will be drained of oil for shipping so they need to be refilled as part of commissioning this lathe in your workshop.

Further information can be seen in the following video and the two photo galleries below …